|

|

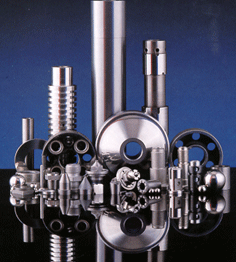

Wear Parts Division

Machining · Grinding · Brazing · Lapping · Assembly

|

Wear Parts Division at Machining Technologies offers you the "Total System" approach

. . . this means we are one-stop source for all your wear parts needs including

machining, grinding, brazing, lapping, assembly and shipment to your specified destination.

Because of our flexible and diverse edge in the industry . . . our Wear Parts Division is able to take your project from start to finish or to provide a required machining operation at a specified stage of manufacture. In addition, Machining Technologies' Quality Control Department was built on and is committed to the concept of "Zero Defects".

Machining Technologies manufactures made-to-order tungsten carbide wear parts in many wear-resistant grades. We have vast experience in the manufacture of a wide range of wear parts for many applications across a diverse field of industries. If wear is a major consideration we are well suited to help you. From our extensive history of producing all kinds of wear parts we have a vast knowledge of tungsten carbide grades coupled with the manufacturing knowhow to get the best wear part performance for nearly every application. Our in-house grinding and finishing expertise enables us to provide the highest quality finished wear parts to achieve increased productivity and extended life from your wear part products. Tungsten carbide wear parts will generally outlast steel by over 10 times and with some special carbide grades the wear part life may increase to 20 or even 30 times. Tungsten Carbide Wear Parts are an ideal choice for use in demanding wear applications such as the control of material flows in pumps. Machining Technologies' ability to be a "one-stop source " covering all aspects of material production, forming and finishing and our ability to flat lap to two light bands, make match lapped sets, and 100% vacuum test wear part components makes us the perfect choice for wear parts for all applications of high pressure pumping systems. Your worn steel components can also be reverse engineered and replaced with high performance tungsten carbide wear parts. Tungsten Carbide Wear Parts are also used for many measurement and inspection applications because of the hardness and low coefficient of thermal expansion, for example Machining Technologies Tooling Balls and Ball Gages. Machining Technologies can help with your die parts. Tungsten Carbide generally offers huge performance advantages over steel dies and die parts. As we produce tooling for our own die sets we understand the need of correct grade selection and profile shape. We can help you find a solution. Solid Tungsten Carbide or Composite Tungsten Carbide/Steel Spraying Components. Tungsten carbide wear parts offer huge advantages over other materials in applications from water jet blasting to paint spraying, atomizing, and drying. We have an extensive history custom making such spray type wear parts from pressing the blanks through finishing complete. We look forward to the opportunity to work with you. |

Flat Lapping

Flat Lapping